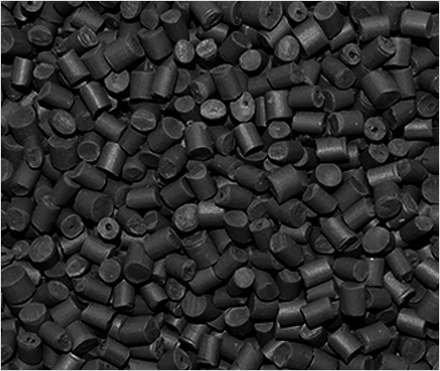

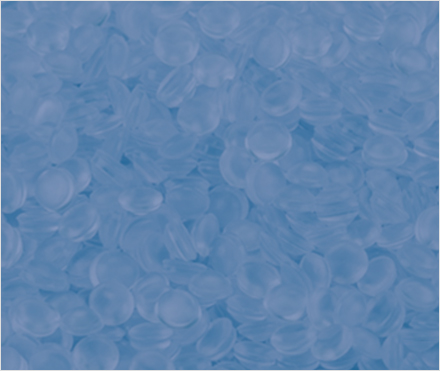

TPEE Polymer (TPE Elastomero Termoplastico) is a block copolymer containing polybutylene terephthalate (PBT) hard segments and polyether soft segments. ATPolymer is a leading manufacturer and supplier in the thermoplastic polyester elastomer market that offers all kinds of TPEE material, including TPEE plastic.

Achieved UL Yellow Card verified vo (1.5mm-6.Omm), fully support cable products to pass the vWw-1 or IEC60332 flame retardance tests.

Surface Resistance 10

Chemical or radiation cross-linking types meet the temperature requirements of 125°C.

No PPS (polystyrene) flame retardant to avoid the risk of stress cracking.

Marine cable designed for 0.6Bg.