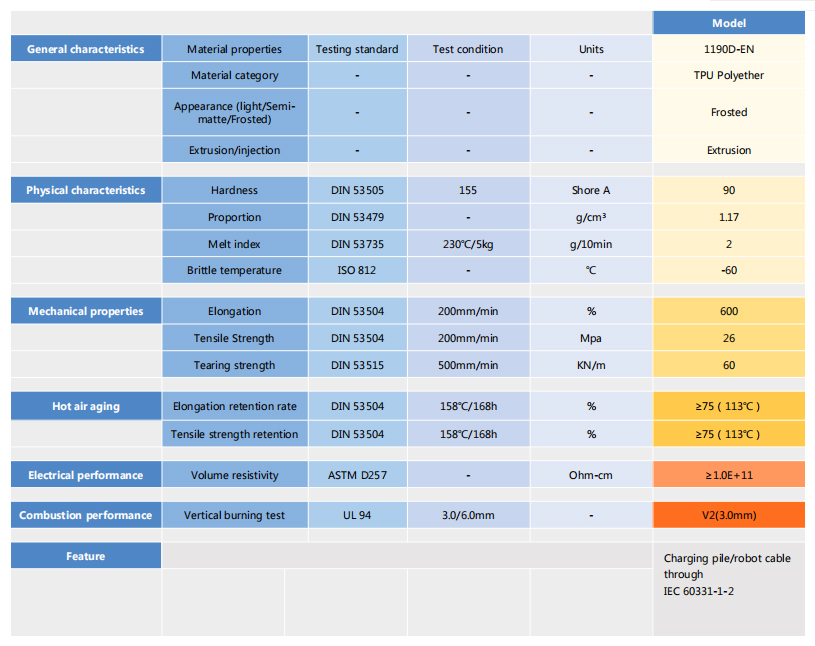

Fully support EV cable to pass EN 50620 GB/T33594 Standard Test (TPU category).

High Secure

Passed the high and low-temperature cyclic winding experiment at - 50℃ ~105 ℃, the tpu material product can function securely in severe cold and continuous high-temperature conditions.

Passed hydrolysis resistance test 2000 Hrs (85℃&85%), the product can function securely with the resistance of winds and rains.

The special formulation Design of anti-mildew guaranteed that even if in the condition of heating and humidity grass area, it can also effectively avoid large-scale mildew on the surface of the cables.

Longer life length

Excellent elastic recovery characteristics at a high temperature can effectively avoid the permanent deformation of heavy current EV cable caused by cable heating in the long-term use process, thus preventing the conductor from breaking at the modification part and extending the service life length impressively.

passed over 50000 wear-resisting tests, effectively preventing EV cable from wearing and cracking caused by repeated dragging under cement and sand conditions for a long time.

More cozy user experience

The introduction of polystyrene (SEBS/SEPS) and polyolefin (tpo polymer) elastomers into the blending modification provides obvious softness, comfortable rubber touch, and fast resilience ability in the application of cable sheath, which makes it easier for terminal users to tow cables while charging, and effectively avoids repeated dragging and straightening under twisted and knotted.

Better stain resistance features, easy-to-wipe surface.

Up-graded appearance

Glossy and frosted (fog) surface for options, which endows cable delicate, comfortable, and high-grade texture, perfectly matches the high-grade new energy vehicles as charging cable materials.

Fully support EV cable to pass GB/T33594 Standard Test (TPEs category).

Cracking resistance: Exclusive patented technology, without PPS (polyphenylene ether), effectively prevents the common stress cracking problem for TPEs sheath in large diameter cable.

Softer and more wear-resistant: The introduction of rubber functional groups provides a more comfortable and soft rubber touch and wear resistance than conventional flame retardant TPEs materials on the market.

Fully support EV cable to pass GB/T33594 Standard Test (TPEs category).

Low-temperature resistance: The product showed better low-temperature flexibility under the test conditions of -40 ℃/8Hrs by comparing with conventional PVC materials: Obvious slower harden in low temperature.

Softer: Under normal temperature conditions, it presents a very soft (70A - 75A) and smooth touch, greatly improving the stiffness of common EV cables;

Wear resistance: Compared with TPEs material, it has better wear resistance.

Easy to process: High extruding processing efficiency and yield rate achieve a significant reduction of cost.

High-class appearance: The unique frosted (fog) surface leads to higher grade texture, has now become the best high cost-effective solution of the EV cable sheath in the southern religion.

TPU stands for "Thermoplastic Polyurethane," which is a type of plastic material that is known for its flexibility, durability, and resistance to abrasion and chemicals. While TPU can be used in a variety of industries, including footwear, sports equipment, and electronics, it is not typically used in the electric vehicle (EV) industry for structural components.

However, TPU can be used in the EV industry for other purposes, such as protective covers for charging ports or battery compartments, as well as insulation for electrical wires and cables. Additionally, TPU can be used in the manufacturing of EV tires, where its durability and resistance to wear and tear can help to extend the lifespan of the tires.

EV (Electric Vehicle) charger cables must be able to withstand a variety of environmental factors, such as temperature changes, moisture, and exposure to chemicals, while also being able to withstand repeated flexing and stretching. TPU can provide these properties, making it an ideal material for EV charger cables.