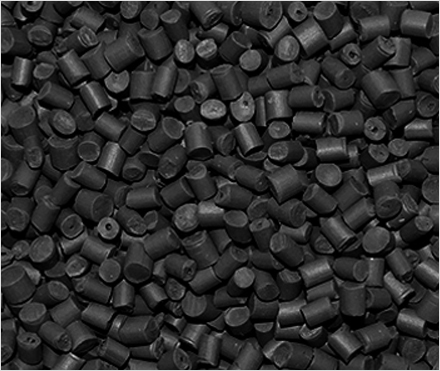

Defender-SM series (1185F) is a patented specialty elastomer polymer (TPUA) developed by ATP specifically for the special construction requirements of lightweight cables. It cost three years from project development, comprehensive testing to large-scale mass production. It is one of the few fiber protection materials in the world that can fully meet the requirements of light cable processing and construction.

1. Meet construction needs:

Easy peeling: The index finger and the thumbnail gently clamped to achieve the peeling of the sheath from the optical fiber, the peeling slit being neat, smooth, without burrs;

Easy tearing: the fiber sheath can be torn by similar to the strength of tearing off an A4 paper, the tearing slit being neat, smooth, without burrs;

2. High security and reliability, support fiber optic cable through various environmental tests and life tests:

Hydrolysis resistance:Pass 1000Hrs hydrolysis resistance test (different model) (85°C/85% RH, 1000 Hrs);

UV resistant: Pass EN 50289-4-17 UV test (mercury lamp(90±10)w/m2, wavelength 300~400nm,60℃, 350Hrs720Hrs) strength and elongation, retention rate ≤50%;

Oil-resistant soaking: The change of the strength and elongation of the paste cable under high temperature conditions (70 ° C / 240Hrs) or light cable immersed in 5 times of grease volume (70 ° C / 240Hrs) ≤ 30%;

High-temperature resistance: After 80 ° C / 42 Days, the change of strength and elongation is ≤ 30%.

| Technical Data Sheet | Model | ||||

| Material Properties | Test Standard | Test Condition | Unit | 1185F-EMS-1589T | |

| General Characteristics | Material Category | - | - | - | |

| Appearance(Light/Semi-matte/Frosted) | - | - | - | ||

| Extrusion/Injection | - | - | - | ||

| Physical Characteristics | Hardness | ISO 48 | 15S | Shore A | 86 |

| Proportion | ISO 1183 | - | g/cm³ | 1.137 | |

| Melt Index | ISO 1133-1:2011 | 190℃/2.16kg | g/10min | 1.2 | |

| Brittle Temperature | ISO 812 | - | ℃ | ||

| Mechanical Properties | Elongation | ISO37:2017 | 200mm/min | % | 234 |

| Tensile Strength | ISO37:2017 | 200mm/min | Mpa | 9.67 | |

| Tearing Strength | ISO34-1:2015 | 500mm/min | KN/m | ||

| Hot Air Aging | Elongation Retention Rate | ISO37:2017 | - | % | |

| Tensile Strength Retention Rate | ISO37:2017 | - | % | ||

| Electrical Performance | Volume Resistivity | ASTM D257 | - | Ohm-cm | |

| Permittivity | ASTM D150 | - | - | ||

| Combustion Performance | Vertical Burning Test | UL 94 | 3.0/6.0mm | - | |

| Oxygen Index | ASTM D2863 | - | % | ||

| Feature | |||||

· Competitive price · Respond immediately · Strong R&D capability · Excellent after-sales service