Thermoplastic Polyether Ester Elastomer Applicable: most kinds of medical equipment and special equipment lines that have biocompatibility, microorganism resistance, alcohol resistance, and other test requirements for sheath materials

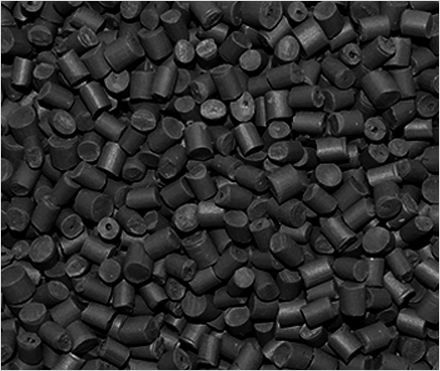

Thermoplastic Polyether Ester Elastomer Product Features:

1. Polyether tpu material, excellent hydrolysis resistance (85℃&85H hydrolysis resistance test ≥30Days);

2. It can pass the biocompatibility test and the microorganism resistance test;

3. Excellent oil resistance, alcohol resistance, and chemical resistance;

4. Can pass -60 ℃ low-temperature winding and low temperature bending test;

5. Appearance feel: dry and smooth, uniform and delicate, and can be processed into a matte/semi-matte surface; excellent wear resistance;

6. Processing performance: excellent processing performance, the production efficiency of 40-100 meters per minute can be achieved by using the same PVC screw machine, and there are very few deterioration performances such as salivation, particles, bulging, and pitting during processing.

| Technical Data Sheet | Model | ||||

| Material Properties | Test Standard | Test Condition | Unit | ||

| General Characteristics | Material Category | - | - | - | |

| Appearance(Light/Semi-matte/Frosted) | - | - | - | ||

| Extrusion/Injection | - | - | - | ||

| Physical Characteristics | Hardness | ISO 48 | 15S | Shore A | |

| Proportion | ISO 1183 | - | g/cm³ | ||

| Melt Index | ISO 1133-1:2011 | 190℃/2.16kg | g/10min | ||

| Brittle Temperature | ISO 812 | - | ℃ | ||

| Mechanical Properties | Elongation | ISO37:2017 | 200mm/min | % | |

| Tensile Strength | ISO37:2017 | 200mm/min | Mpa | ||

| Tearing Strength | ISO34-1:2015 | 500mm/min | KN/m | ||

| Hot Air Aging | Elongation Retention Rate | ISO37:2017 | - | % | |

| Tensile Strength Retention Rate | ISO37:2017 | - | % | ||

| Electrical Performance | Volume Resistivity | ASTM D257 | - | Ohm-cm | |

| Permittivity | ASTM D150 | - | - | ||

| Combustion Performance | Vertical Burning Test | UL 94 | 3.0/6.0mm | - | |

| Oxygen Index | ASTM D2863 | - | % | ||

| Feature | |||||

· Competitive price · Respond immediately · Strong R&D capability · Excellent after-sales service