Thermoplastic polyurethane (TPU compounds) have emerged as indispensable materials in industries demanding high performance, durability, and environmental resistance. From new energy vehicles (NEVs) to 5G communications and medical devices, TPU's unique balance of elasticity, chemical resistance, and thermal stability makes it an ideal choice for cutting-edge applications. ATP Polymer Technology Co., Ltd. (ATP), a leading global manufacturer of advanced polymer compounds, stands out in the market by delivering high-performance TPU solutions tailored for industry-specific challenges.

This article explores the key characteristics of TPU compounds, highlights the competitive advantages of choosing ATP as a polymer material partner, and includes a comparative analysis to illustrate why ATP's formulations outperform conventional alternatives.

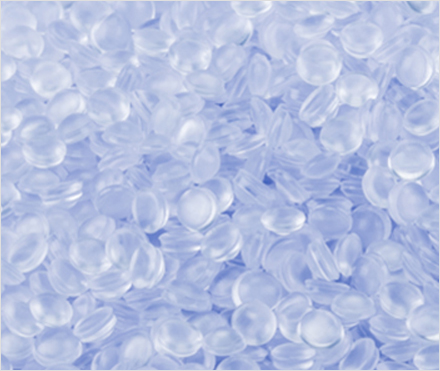

TPU (thermoplastic polyurethane) combines rubber-like elasticity with thermoplastic processability, making it suitable for diverse applications.

Exceptional Mechanical Strength and Flexibility: TPU exhibits high tensile strength and elongation, ensuring durability even under repeated flexing, making it ideal for cables, seals, and connectors.

Chemical and Environmental Resistance: Unlike conventional rubbers, TPU resists oils, solvents, and hydrolytic degradation, enhancing its lifespan in automotive and industrial environments.

Flame Retardancy: Many of ATP's TPU formulations meet UL94 V-0 and CPR standards, crucial for EV battery components and high-voltage cabling.

Thermal Stability: ATP's TPU compounds can withstand temperatures from -40°C to 120°C, making them suitable for cooling systems and under-the-hood automotive parts.

Aesthetic and Functional Versatility: Available in translucent, colored, or soft-touch finishes, TPU enhances product designs in consumer electronics, medical devices, and automotive interiors.

As a national high-tech enterprise, ATP Polymer Technology distinguishes itself through cutting-edge R&D, stringent quality control, and sustainability-driven innovation:

Expert-Led R&D Team: ATP's research team includes PhD and Master's degree holders from top institutions, ensuring material formulations stay at the forefront of polymer science.

CNAS-Certified Laboratory: The company operates a high-standard materials lab with advanced testing equipment, ensuring compliance with EU CPR, GB31247, and other global standards.

Sustainable Solutions: ATP focuses on environmentally friendly polymer materials, reducing hazardous additives while maintaining high performance.

High Production Capacity: With an annual output of 12,000 tons, ATP ensures reliable supply for industries such as automotive, aerospace, and 5G communications.

ATP's TPU materials are widely adopted across emerging and high-value sectors:

New Energy Vehicles (NEVs): Used in battery seals, high-voltage cables, and cooling hoses, where chemical resistance, flame retardancy, and flexibility are critical.

5G & Consumer Electronics: Ideal for durable cable insulation and flexible wearables due to high dielectric strength and aesthetic versatility.

Medical Devices: ATP's biocompatible and sterilizable TPU grades are used in surgical tubing and wearable health monitors.

Industrial & Military: The material's wear resistance and extreme-temperature performance support robotics, defense, and aerospace applications.

The table below highlights why ATP's TPU compounds outperform traditional materials like PVC, silicone, and standard rubber:

Property | ATP TPU Compounds | PVC | Silicone Rubber |

Tensile Strength (MPa) | 30-60 | 10-30 | 5-10 |

Elongation at Break (%) | 300-800 | 100-300 | 200-700 |

Flame Retardancy | UL94 V-0 | Limited | Self-extinguishing |

Chemical Resistance | Excellent | Poor | Moderate |

Temperature Range (°C) | -40 to 120 | -10 to 60 | -60 to 200 |

Processing Efficiency | High (thermoplastic) | Medium | Low (thermoset) |

ATP's TPU offers a superior balance of mechanical strength, flame resistance, and processability, making it a preferred material for advanced applications.

With specialized expertise, state-of-the-art facilities, and a commitment to innovation, ATP Polymer Technology delivers high-performance TPU compounds that meet the evolving demands of various industries. Whether for next-gen EVs, medical devices, or smart electronics, ATP's formulations provide enhanced durability, safety, and sustainability compared to conventional materials.

For manufacturers seeking reliable, high-quality TPU solutions, ATP stands as a trusted global partner in polymer technology.