As a professional leading polymer compound manufacturing company, we would like to share with you the topic difference between PVC and TPU. First we would give a general introduction to TPU. Then we would compare the two from the aspect of material, that is, pvc vs tpu material.

TPU is a mature environmental protection material with excellent characteristics of high tension, strong toughness and aging resistance. At present, TPU has been widely used in medical treatment, electronics, industry, and sports. It has the characteristics of high strength, good toughness, wear resistance, cold resistance, oil resistance, water resistance, aging resistance and climate resistance unmatched by other plastic materials. At the same time, it has many excellent functions such as TPU for Mining cable, high water resistance, moisture permeability, wind resistance, cold resistance, antibacterial, mildew resistance, heat preservation, UV resistance and energy release. TPU can be divided into the polyester type and polyether type according to the molecular structure, and can be divided into injection molding, extrusion and blow molding according to the processing mode.

TPU: It is widely used in tpe cable jacket, daily necessities, sporting goods, toys, decorative materials and other fields

PVC: It can be used to make anti-corrosion pipelines, pipe fittings, oil pipelines, centrifugal pumps and blowers. PVC hard board is widely used in the chemical industry to make the lining of various storage tanks, corrugated boards of buildings, door and window structures, wall decorations and other building materials.

TPU: TPU is a mature environmental protection material with excellent high tension, toughness and aging resistance. It has the characteristics of high strength, good toughness, wear resistance, cold resistance, oil resistance, water resistance, aging resistance and climate resistance unmatched by other plastic materials. At the same time, it has many excellent functions, such as high water resistance, wind resistance, cold resistance, antibacterial, mildew resistance, heat preservation, UV resistance and energy release.

PVC: PVC has good electrical insulation performance and chemical stability, and can be used as low-frequency insulation material. Due to the poor thermal stability of PVC, heating for a long time will lead to its decomposition, thus releasing HCl gas and discoloring PVC. Therefore, its application range is narrow, and the service temperature is generally between - 15 ~ 55 ℃.

UV-resisitance TPU in ATP company

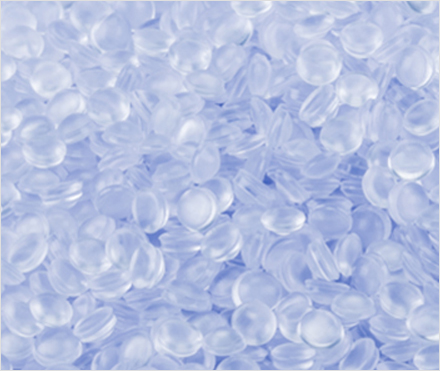

TPU: tpu compound is a high molecular material formed by the reaction and polymerization of diisocyanate molecules such as diphenylmethane diisocyanate (MDI) or toluene diisocyanate (TDI) with macromolecular polyols and low molecular Polyols (chain extender).

PVC: PVC material is one of the largest plastic products in the world. It is cheap and widely used. PVC resin is a white or light yellow powder, which can not be used alone and must be modified.

| Characteristics | TPU | PVC |

| Common Uses | TPE cable jackets, Daily necessities, Sporting goods, Toys, Decorative materials | Anti-corrosion pipelines, Pipe fittings, Oil pipelines, Centrifugal pumps, Blowers, PVC hard board for chemical industry, Lining of storage tanks, Corrugated boards for buildings, Door and window structures, Wall decorations |

| Environmental Impact | Mature environmental protection material | Widely used, but environmental concerns due to release of HCl gas upon decomposition |

| Mechanical Properties | Excellent high tension Excellent toughness Aging resistance High strength Wear resistance Cold resistance Oil resistance Water resistance Climate resistance | Good electrical insulation Chemical stability Limited thermal stability |

| Composition | High molecular material formed by reaction and polymerization of diisocyanate molecules (MDI or TDI) with macromolecular polyols and low molecular polyols (chain extender) | PVC resin, typically modified for specific applications |

| Temperature Range | Broad temperature range | Generally between -15°C to 55°C |

| Additional Features | Antibacterial, Mildew resistance, Heat preservation, UV resistance, Energy release, Wind resistance | Low-frequency insulation, Must be modified for specific applications |

For unmatched durability and resistance to wear, chemicals, and harsh environments, TPU is the top choice. It withstands rugged conditions and heavy use, making it ideal for demanding applications. PVC, while less robust, still provides moderate resilience and offers a reliable, lower-cost option for applications with lighter performance needs.

High-temp TPU in ATP company

TPU is highly flexible, retaining its shape even under stress, which makes it perfect for products requiring elasticity, such as phone cases or athletic equipment. In contrast, PVC offers more rigidity or semi-rigidity, making it suitable for static uses like piping or wire insulation, where flexibility is less important.

As an eco-friendlier choice, TPU is recyclable and avoids releasing harmful chemicals during production and disposal. PVC is less environmentally friendly due to its chlorine content, which can release toxins when improperly discarded. This makes TPU a preferred choice for eco-conscious applications focused on sustainability.

PVC is generally a more affordable material, making it well-suited for budget-sensitive projects with less demanding performance requirements. TPU, though more expensive, offers exceptional durability and flexibility that justify its price for applications needing high performance or long-term reliability.

From the perspective of a TPU material supplier, these points illustrate why TPU is increasingly favored across industries. Its superior performance, flexibility, and environmental benefits make TPU a prime material choice, especially for applications that demand high durability and align with sustainability goals.