In an era where fire safety demands are escalating across industries, fire-resistant low smoke zero halogen (LSZH) materials have emerged as the definitive solution. As a pioneer in polymer innovation, ATP Polymer Technology has established itself as a global leader in developing advanced LSZH compounds that combine exceptional fire resistance with environmental sustainability.

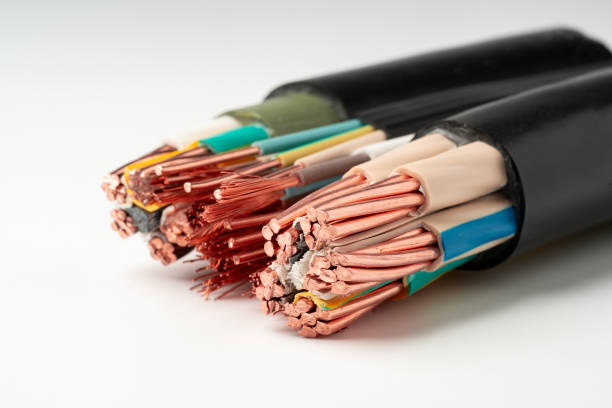

Traditional cable insulation materials like PVC pose severe risks in fire emergencies, releasing toxic fumes and dense smoke that jeopardize lives and equipment. ATP's fire-resistant LSZH technology addresses these threats through:

Self-extinguishing properties that prevent flame propagation.

Significantly reduced smoke emission, maintaining visibility during evacuation.

Zero halogen content, eliminating toxic gas production.

Enhanced thermal stability for high-temperature applications.

These characteristics make LSZH indispensable for critical infrastructure projects in rail transit, power plants, and high-rise buildings where fire safety is non-negotiable.

The superiority of ATP's fire-resistant LSZH becomes evident when examining key safety metrics:

Performance Characteristic | Conventional PVC | Standard LSZH | ATP Fire-Resistant LSZH |

Flame Retardancy (LOI) | 20-25% | 28-32% | 34-40% |

Smoke Density (Ds) | ≥600 | ≤150 | ≤50 |

Halogen Content | High (>30%) | 0% | 0% |

Toxicity (LC50) | Highly toxic | Non-toxic | Non-toxic |

Acid Gas Emission (pH) | < 2.0 | >4.3 | >5.0 |

Compliance Standards | Limited approvals | CPR/EN 50575 | CPR+GB31247+NFPA130 |

This comparative analysis demonstrates how ATP's advanced formulations surpass both traditional materials and conventional LSZH in critical fire safety parameters.

ATP's leadership in fire-safe polymers stems from its:

CNAS-certified fire testing laboratory equipped with state-of-the-art

Cone calorimeters for smoke toxicity analysis.

Vertical/horizontal flame test chambers.

Oxygen index determination systems.

Expert R&D team with extensive experience in

Nano-scale flame retardant dispersion.

Synergistic additive combinations.

Polymer molecular structure optimization.

Proprietary compounding techniques that achieve

UL94 V-0 ratings at 0.4mm thickness.

CTI values >600V for electrical applications.

Long-term thermal aging resistance at 105°C+.

ATP's fire-resistant LSZH materials protect critical systems across multiple sectors:

Mass Transit Systems

Flame-retardant cable coatings for underground railways.

Smoke-suppressed wiring in passenger carriages.

Energy Infrastructure

Fireproof insulation for nuclear power plants.

High-temperature resistant jacketing for oil/gas facilities.

Smart Buildings

Safety-enhanced wiring for high-rise emergency systems.

Halogen-free data cables for modern office complexes.

Defense Applications

Damage-resistant materials for naval vessel wiring.

Flammability-controlled components in aerospace systems.

As global fire safety regulations become increasingly stringent, ATP Polymer Technology continues to redefine industry standards with its fire-resistant LSZH solutions. By combining cutting-edge materials science with rigorous testing protocols, ATP delivers products that genuinely protect people, property, and the environment. The company's commitment to continuous innovation ensures its position as the partner of choice for the world's most demanding fire safety applications.