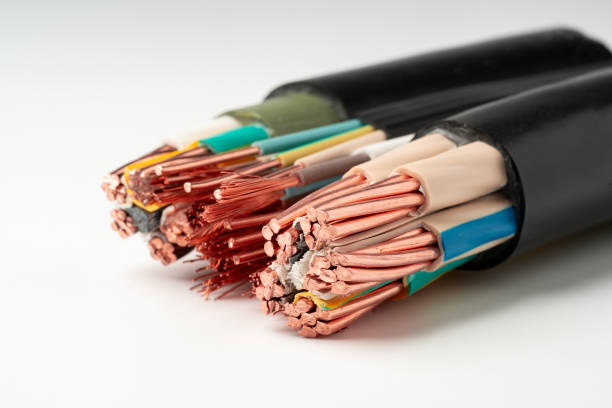

As fire safety regulations tighten worldwide, industries are transitioning from conventional materials to advanced fire-resistant LSZH (Low Smoke Zero Halogen) compounds. Developed by ATP Polymer Technology, these innovative materials combine exceptional flame retardancy with minimal smoke and zero toxic gas emissions, making them indispensable for public spaces, transportation networks, and industrial applications. Unlike traditional PVC or halogenated materials, fire-resistant LSZH ensures life-saving performance in emergency situations while meeting the most stringent global safety standards.

Uncompromising Fire Safety Performance

Halogen-Free Composition – Eliminates toxic gas release (HCI, bromides) that endangers lives and equipment.

Ultra-Low Smoke Emission (Ds <60) – Maintains visibility for safe evacuation in confined spaces.

Self-Extinguishing Properties – Achieves UL94 V-0 flame retardancy, significantly reducing fire spread.

Regulatory Compliance for Global Markets

EU CPR (Construction Products Regulation) Certified.

Meets EN 45545 (Railways), IEC 60332-1/3 (Flame Spread), and UL 1685 (Vertical Flame Test).

China GB31247 (Flame Retardant Classification) & US NFPA Fire Codes.

Durability in Extreme Conditions

Resists mechanical stress, vibrations, and abrasion in industrial, automotive, and aerospace wiring.

Operating range: -40°C to 105°C – Suitable for harsh outdoor and indoor environments.

UV and chemical-resistant formulations for applications requiring long-term reliability.

Industry | Application | Why LSZH is Critical |

Railways & Metro Systems | Underground tunnels, train interiors, signaling | Non-toxic smoke, compliance with EN 45545 |

Building Wiring | High-rise buildings, hospitals, data centers | Reduces fire spread, safer evacuations |

Military & Aerospace | Aircraft wiring, naval vessels | Lightweight, non-corrosive smoke |

EV & Battery Cables | Charging stations, battery management | Prevents thermal runaway risks |

Industrial Automation | Robotics, control systems, industrial panels | Resists oil, chemicals & heat |

Property | PVC (FR) | Halogenated Flame Retardant | Fire-resistant LSZH (ATP) |

Smoke Density (Ds Max) | 600–900 (Hazardous) | 200–400 (Still toxic) | <60 (Optimal Visibility) |

Toxic Gas Emission | High (HCl, dioxins) | Moderate (Brominated gases) | Zero Halogens (Safe Air) |

Flame Spread (IEC 60332-3A) | Fails vertical tests | Passes with limitations | Fully Compliant (Cat A/B) |

Temperature Resistance (°C) | 70–80 (Limited use) | 90 (Degrades under heat) | -40 to 105 (Wide Range) |

Global Standards Compliance | Basic certifications | Regional restrictions | CPR, NFPA, EN 45545, UL Certified |

ATP's Fire-resistant LSZH outperforms traditional materials in safety, durability, and regulatory acceptance, making it the best choice for modern infrastructure projects.

As a CNAS-certified R&D leader with 12,000-ton annual production capacity, ATP's fire-resistant LSZH solutions incorporate:

Nano-enhanced flame-retardant additives – For better mechanical & thermal stability.

Low-smoke intumescent technology – Minimizes smoke release without sacrificing flexibility.

Custom formulations – Optimized for high-voltage cables, aerospace, and medical applications.

Trusted supplier for global clients in rail, construction, and industrial automation.

Full compliance with EU, US, and China fire regulations.

Engineered for extreme environments with superior longevity.

As industries adopt stricter fire prevention standards, fire-resistant LSZH stands out as the ultimate flame-retardant solution. ATP Polymer Technology's cutting-edge formulations provide unmatched safety, durability, and regulatory compliance—ensuring protection for people, infrastructure, and critical systems. Whether for smart buildings, mass transit, or energy storage, fire-resistant LSZH is setting a new benchmark in material safety.