As industries demand higher safety standards, flame-retardant materials like fire-resistant LSZH (Low Smoke Zero Halogen) and FRPE (Flame-Retardant Polyethylene) have become essential in electrical, automotive, and construction applications. While both materials enhance fire safety, they differ significantly in composition, performance, and use cases. ATP Polymer Technology Co., Ltd., a leading innovator in polymer compounds, specializes in manufacturing high-quality LSZH and FRPE for critical applications.

This article explores the key differences between fire-resistant LSZH and FRPE, including their chemical properties, fire resistance mechanisms, and ideal applications. A comparison table will highlight their technical distinctions, helping engineers and manufacturers choose the right material for their needs.

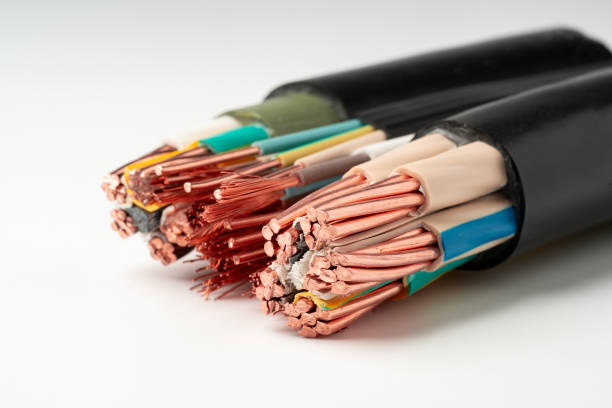

Fire-resistant LSZH is a halogen-free polymer designed to minimize toxic smoke and corrosive gas emissions during combustion. It is widely used in public spaces, tunnels, and data centers where human safety is paramount.

FRPE, on the other hand, is a flame-retardant polyethylene that incorporates additives to resist ignition and slow fire spread. While not inherently halogen-free, advanced FRPE formulations can achieve high fire safety ratings for industrial wiring and power transmission systems.

Both materials are crucial for fire prevention, but their material science and applications differ significantly.

Fire-Resistant LSZH

Halogen-free formulation (no chlorine or bromine), reducing toxic fume risks.

Smoke suppression technology using metal hydroxides (e.g., aluminum/magnesium hydroxide).

Zero acidic gas emissions, making it safe for confined spaces like subways and hospitals.

FRPE (Flame-Retardant Polyethylene)

Typically contains flame-retardant additives (e.g., antimony trioxide, phosphorous compounds).

Some grades may release small amounts of halogenated compounds depending on formulation.

Designed to self-extinguish while maintaining mechanical strength.

While LSZH prioritizes human safety and environmental compliance, FRPE focuses more on mechanical durability with flame retardancy in industrial settings.

The table below highlights the key technical differences between these two materials:

Property | Fire-Resistant LSZH | FRPE |

Halogen Content | Zero-halogen, non-toxic | May contain halogen additives |

Smoke Density | Very low smoke emission | Moderate smoke emission |

Toxicity | Non-corrosive, safe for humans | Varies (some formulations emit acidic gases) |

Flame Retardancy | Meets CPR, IEC 60332 | Meets UL94, IEC 60754 |

Primary Applications | Public transport, buildings | Industrial cables, power systems |

Environmental Impact | Eco-friendly, recyclable | Depends on halogen content |

LSZH is superior in low-smoke, toxicity reduction, and human safety, while FRPE offers robust mechanical properties for industrial use.

Fire-Resistant LSZH Dominates in

Rail transit & tunnels (preventing toxic smoke accumulation).

Data centers & telecom wiring (minimizing corrosive gas risks).

Medical and public buildings (ensuring safe evacuation).

FRPE Preferred for

Power transmission cables (high mechanical strength needed).

Industrial electrical conduits (flame resistance + flexibility).

Military and aviation wiring (heat resistance & durability).

As a CNAS-certified polymer innovator, ATP Polymer Technology stands out for:

Advanced R&D: Expert-led team from top Chinese research institutes.

Sustainability Focus: Eco-conscious LSZH and optimized FRPE formulations.

Strict Compliance: Meets CPR, UL94, GB31247, and EU standards.

High Production Capacity: 12,000-ton annual capacity ensures reliable supply.

Whether your project requires smoke-free safety (LSZH) or industrial-grade durability (FRPE), ATP provides custom-engineered solutions.

Fire-resistant LSZH is the best choice for human-centric environments due to its zero-toxicity and smoke suppression, while FRPE excels in industrial and high-durability applications. ATP Polymer Technology ensures high-performance options for both safety and mechanical resilience, making it a trusted supplier in the polymer industry.