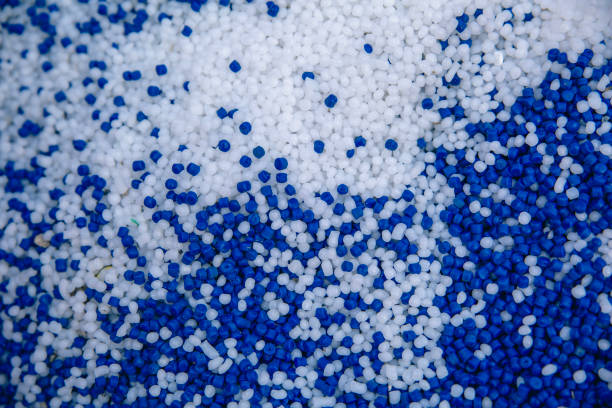

In today's rapidly advancing industrial landscape, the demand for high-performance insulating materials that can withstand extreme conditions continues to grow. High density cross linked polyethylene (XLPE) has emerged as a leading solution, offering unmatched durability, thermal resistance, and electrical insulation properties. Manufactured by ATP Polymer Technology, a pioneer in advanced polymer compounds, XLPE is widely used in power distribution, automotive wiring, renewable energy systems, and industrial cables. Unlike conventional polyethylene, chemically cross-linked XLPE provides superior mechanical strength, tear resistance, and long-term stability—making it the preferred material for mission-critical applications.

Enhanced Thermal and Chemical Resistance

Withstands operating temperatures up to 90°C (short-term up to 130°C).

Resistant to oil, solvents, and UV degradation—ideal for industrial and outdoor applications.

Maintains structural integrity under thermal cycling, preventing premature failure.

Superior Mechanical Performance

Higher tensile strength than standard PE, reducing damage during installation and flexing.

Outstanding tear resistance, crucial for cables in mining, automation, and heavy machinery.

Improved abrasion resistance for extended service life.

Excellent Electrical Insulation Properties

Low dielectric constant, minimizing signal loss in power transmission and high-frequency cables.

Meets IEC 60502, BS 5467, and other stringent standards.

These characteristics make high density cross linked polyethylene indispensable for industries where reliability is non-negotiable.

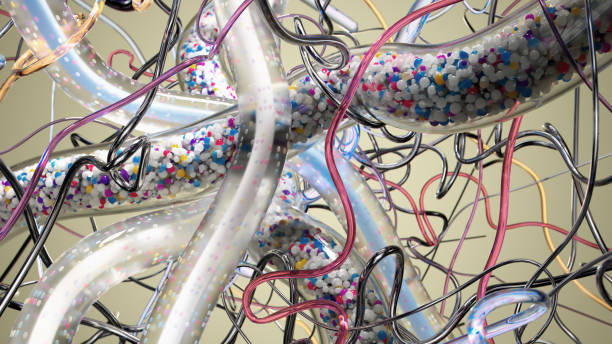

Power & Energy Transmission

Medium and high-voltage power cables for utilities.

Underground and submarine cables in harsh environments.

Solar and wind farm connections, ensuring durability against weathering and thermal stress.

Automotive & Electric Vehicles

High-voltage battery cables for EVs, resistant to heat and tearing.

Charging station wiring, ensuring safety and longevity under repeated bending.

Industrial & Automation Cables

Robotic arm and CNC machine cables requiring high flexibility and durability.

Mining and oilfield cables that endure mechanical abuse and chemical exposure.

Building & Infrastructure Wiring

FIRE-PROOF XLPE for CPR-certified building wiring.

Rail and metro power cables with flame retardancy and low-smoke emission.

Property | Standard LDPE / HDPE | LSZH Material | PVC Insulation | ATP’s XLPE |

Max. Continuous Temp. | 75°C | 90°C | 70°C | 90–105°C |

Tear Resistance (N/mm) | 10–25 | 20–40 | 15–30 | 35–60 |

Dielectric Strength (kV/mm) | 18–22 | 20–28 | 15–20 | 28–35 |

Flame Retardancy (UL94) | HB | V-0 | V-2 | V-0 (FR Grades) |

Chemical Resistance | Moderate | High | Low | Very High |

Lifetime Expectancy (Years) | 15–20 | 20–25 | 10–15 | 25–30+ |

This table highlights why high density cross linked polyethylene outperforms alternatives in harsh and high-load applications.

ATP Polymer Technology advances XLPE performance through cutting-edge formulations:

Nanocomposite-reinforced XLPE for higher mechanical resilience.

Halogen-free flame retardant grades compliant with CPR & IEC standards.

UV-stabilized XLPE for long-term outdoor exposure.

With a CNAS-certified R&D lab and 12,000-ton annual production capacity, ATP ensures consistent quality and rapid customization for global markets.

As industries demand lighter, tougher, and more efficient material solutions, high density cross linked polyethylene stands out as the ultimate choice for power transmission, automation, and EV applications. ATP Polymer Technology's expertise in XLPE innovation delivers unmatched performance, safety, and reliability, shaping the future of sustainable polymer solutions.