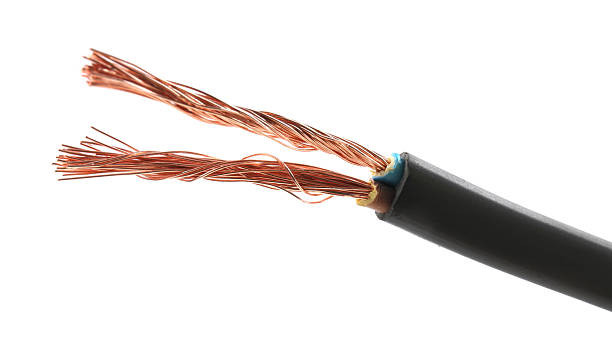

As industrial automation, robotics, and IoT applications expand globally, the demand for durable, flexible, and high-performance cable solutions has never been higher. ATP Polymer Technology, a leading innovator in polymer materials, specializes in TPE cable jacket material that sets new benchmarks in mechanical resilience, environmental resistance, and long-term reliability. Designed for robotic control cables, industrial automation systems, and harsh-environment wiring, ATP's TPE formulations ensure superior abrasion resistance, oil/chemical endurance, and signal integrity—making them the material of choice for engineers across industries.

While PVC, XLPE, and rubber have long been used in cable jacketing, TPE cable jacket material offers significant advantages:

Exceptional flexibility (Shore A 60–95) for high-motion applications like robotic arms and CNC machinery.

UV, oil, and hydrolysis resistance, critical for outdoor installations or factory floors.

Halogen-free flame retardancy, meeting CPR, UL, and IEC 60332 standards.

Lightweight and easy to process, reducing manufacturing costs and energy use.

Enhanced dielectric properties, ensuring stable signal transmission in 5G and high-frequency networks.

These properties make TPE cable jackets indispensable for industries requiring longevity, safety, and dynamic performance.

Robotics & Automation Control Cables

Continuous-flex jackets for industrial robots and articulated arms that endure millions of cycles.

Pliability for tight-bend routing in cobots and automated assembly lines.

Industrial Machinery & Energy Systems

Oil-resistant cables for hydraulic systems and offshore wind turbines.

Abrasion-resistant sleeving for mining and construction equipment.

Automotive & EV Wiring Harnesses

High-temperature resistance (up to 125°C) for engine compartments.

Shock-absorbing layers in battery management system (BMS) cables.

Consumer Electronics & Medical Devices

Soft-touch USB/charging cables with enhanced durability.

Sterilizable TPE insulation for medical robot wiring.

The table below showcases why TPE cable jacket material surpasses conventional options in demanding applications:

Property | PVC | XLPE | Silicone Rubber | ATP's TPE |

Flexibility (Shore A) | 80–95 (stiff) | 75–90 | 20–60 | 60–95 (adjustable) |

Continuous Flex Life | Poor | Moderate | Good | Excellent |

Oil/Chemical Resistance | Low | High | Moderate | High |

Flame Retardancy | Halogenated | Good | Poor | Halogen-free (LSZH) |

Temperature Range | -20°C to 80°C | -50°C to 90°C | -60°C to 200°C | -40°C to 125°C |

Processing Efficiency | Low (high energy) | Moderate | High (costly) | High (low energy) |

This data highlights ATP's TPE superiority in dynamic, harsh, and high-performance environments.

ATP Polymer Technology continues to push boundaries with its TPE cable jacket solutions:

Self-healing TPEs for minor cut/wear resistance in robotic cables.

Electrically conductive TPEs for EMI shielding in industrial networks.

Bio-based TPEs made from renewable resources, supporting sustainability goals.

With CNAS-certified testing facilities and 12,000-ton annual production capacity, ATP ensures consistent quality, fast prototyping, and compliance with international standards such as RoHS, REACH, and UL.

As industries embrace Industry 4.0, smart factories, and autonomous robotics, TPE cable jacket material will remain pivotal in ensuring durable, high-speed, and environmentally responsible cable systems. ATP Polymer Technology's expertise guarantees solutions that optimize performance, safety, and cost efficiency—making TPE the material of choice for next-generation connectivity challenges.